Study on Preparation of Ceramsite from a Laumontite Tailings from Gansu and Its Performance

-

摘要:

以甘肃某浊沸石尾矿为原料,凹凸棒石黏土为黏结剂,煤粉为造孔剂,通过高温煅烧工艺制备多孔陶粒,并系统研究了黏结剂添加量、煅烧温度、煅烧时间和煤粉用量等因素对陶粒样品性能的影响规律,得出了优化的制备工艺,并运用SEM、XRD表征手段对样品的微观形貌及物相组成进行检测分析。结果表明:在浊沸石尾矿、凹凸棒石黏土与煤粉的质量比为42.5 GA6FA 42.5 GA6FA 15,煅烧温度1 100℃、煅烧时间30 min、升温速度20℃/min的条件下,制备的陶粒样品的堆积密度692 kg/m3,压裂力116.4 N,吸水率25.3%,筒压强度4.7 MPa,符合国标要求。所制备的浊沸石尾矿陶粒表面多孔,且高温条件下原料中的浊沸石、坡缕石等矿相转化为石英和钠长石。该技术为砂石尾矿综合利用提供了一种有效途径。

Abstract:Using some kind of laumontite tailing in Gansu Province as raw material, attapulgite clay as binder, and coal powder as pore-forming agent, the porous ceramsite was prepared by a high-temperature calcination process. The effects of the amount of binder, calcination temperature, calcination time and the amount of pulverized coal on the properties of ceramsite samples were systematically studied, and the optimized preparation process was obtained. The microstructure and phase composition of the samples were detected and analyzed by SEM and XRD characterization methods. The results show that the optimal mass ratio of laumontite tailings, attapulgite clay and coal powder is 42.5 GA6FA 42.5 GA6FA 15, the calcination temperature is 1 100 ℃, the calcination time is 30 min, and the heating rate is 20 ℃/min. The bulk density of the obtained sample prepared under optimal conditions is up to 692 kg/m3, the fracturing force is 116.4 N, the water absorption is 25.3%, and the cylinder compressive strength is 4.7 MPa. The performance meets the requirements of the national standard for the ceramsite. In addition, the prepared ceramsite is porous, and the mineral phases such as laumontite and palygorskite in the raw material are transformed into quartz and albite under high temperature conditions. This technology provides an effective way for the comprehensive utilization of sand and gravel aggregate tailings.

-

Keywords:

- laumontite tailings /

- ceramsite /

- attapulgite clay /

- coal powder /

- comprehensive utilization

-

近年来,随着房地产行业、交通基建等领域的快速发展,砂石骨料已成为公路、铁路、建筑和水利等基础设施建设不可或缺且用量最大的基础材料之一。据统计,我国每年的砂石骨料用量超200亿t,并且其需求量仍在持续增加[1-4]。而传统砂石料磨碎、筛分加工过程中会不可避免地产生大量细颗粒尾矿。该尾矿颗粒细、含泥量大,极难处置,大量堆存不仅会造成有限土地资源的巨大浪费,而且还会带来严重的生态环境和安全问题。因此,迫切需要拓展一种细颗粒砂石尾矿综合利用的新途径[5]。

陶粒是经过高温烧结或免烧工艺制备而成的颗粒物或柱状物产品[6]。由于其具有质轻、抗冻、抗震等优良的使用性能,近年来被广泛应用于建筑、环保和绿化等行业[7-10]。陶粒的生产原料来源广泛,近年来主要集中在粉煤灰、污泥以及矿物尾矿等固体废弃物上[11-16]。利用工业固废作为陶粒的主要原料,不仅适应市场对于轻质建材、环保材料的重大需求,而且还能获得一定的经济和社会效益。本文中的浊沸石尾矿是甘肃某砂石骨料加工过程产生的一种细颗粒尾矿。目前,国内外针对此类浊沸石加工利用研究较少。张铨昌等[17]对其理化特性及地质产状进行了研究,提出了浊沸石是一种有用的矿物,但未对其利用方式进行详细说明。本文在对甘肃某公司产生的浊沸石尾矿进行充分表征分析的基础上,复配一定的凹凸棒石黏土与煤粉制备一种多孔陶粒,并运用SEM、XRD表征手段对陶粒样品的微观形貌及物相组成进行分析,还探究了黏结剂添加量、煅烧温度、煅烧时间以及煤粉用量对样品性能的影响规律,得出了其优化的制备工艺及机理。

1. 试验

1.1 试验原料

1.1.1 浊沸石尾矿

本研究所采用的浊沸石尾矿来自甘肃某公司,其主要的理化性质及成分分析见表 1~表 3。由表 1可知,该尾矿本身粒度较小,D97仅为19.02 μm,因此在制备多孔陶粒过程中无需经过破碎、磨矿等工序,即可满足造粒需求。由表 2可知,其主要化学成分为SiO2与Al2O3,无论是成分还是含量均符合制备陶粒原料的质量要求(SiO2:40%~79%,Al2O3:10%~25%,助溶剂:13%~26%)。由表 3可知,其主要矿物成分为浊沸石,且含有一定量的绿泥石与长石。浊沸石具有良好的阳离子交换与吸附性能,绿泥石则有助于造粒,而长石可起到助熔作用,可有效降低陶粒的煅烧温度。

表 1 浊沸石尾矿粒度分析结果Table 1. Granularity analysis results of laumontite tailings粒度级 D10 D50 D90 D97 粒径/μm 1.43 6.42 16.71 19.02 表 2 浊沸石尾矿的主要化学成分分析结果Table 2. The main chemical components and content analysis results of laumontite tailings氧化物 SiO2 Al2O3 CaO Fe2O3 MgO K2O Na2O TiO2 含量/% 47.4 18.6 12.2 12.3 4.88 1.19 1.47 1.09 表 3 浊沸石尾矿的XRD物相分析结果Table 3. XRD phase analysis results of laumontite tailings矿物 沸石 绿泥石 长石 石英 磁铁矿 云母 含量/% 52.8 18.4 18.0 5.9 2.7 2.2 1.1.2 凹凸棒石黏土与煤粉

所采用的黏结剂为甘肃张掖地区所产的凹凸棒石黏土,其化学成分及物相分析结果见表 4和表 5。由表 4可知,该凹凸棒石黏土的主要化学成分为SiO2;由表 5可知,该凹凸棒石黏土的主要矿物成分为石英、坡缕石及白云石等,黏土成分能够满足陶粒制备需求,而且原料成本较低。煤粉为宁夏回族自治区石嘴山市宁夏煤业有限责任公司洗选中心太西洗煤厂所产跳汰中煤,灰分为39.1%。其灰分化学成分组成及物相分析结果见表 6和表 7,该煤粉种灰分主要成分为高岭石,属黏土矿物,可辅助增加生料球黏性,利于造粒。

表 4 凹凸棒石黏土的主要化学成分分析结果Table 4. The main chemical components and content analysis results of attapulgite clay氧化物 SiO2 CaO Al2O3 MgO 其他 含量/% 87.6 4.5 3.6 3.1 1.2 表 5 凹凸棒石黏土的XRD物相分析结果Table 5. XRD phase analysis results of attapulgite clay矿物 石英 坡缕石 白云石 含量/% 75.4 16.7 7.9 表 6 煤粉灰分的主要化学成分分析结果Table 6. The main chemical components and content analysis results of pulverized coal ash氧化物 SiO2 Al2O3 Fe2O3 CaO MgO K2O 其他 含量/% 48.10 27.70 10.00 6.81 2.45 2.08 2.84 表 7 煤粉灰分的XRD物相分析结果Table 7. XRD phase analysis results of pulverized coal ash矿物 高岭石 石英 菱铁矿 白云石 含量/% 69.3 15.1 10.4 5.2 1.2 陶粒制备方法

按一定质量比计量称取浊沸石尾矿与凹凸棒石黏土,混合均匀后放入滚筒造粒机中进行造粒得到生料球,然后将生料球置于干燥箱中干燥12 h,最后将干燥后的生料球置于电阻炉中进行煅烧。煅烧结束后随炉降温,待温度降低至室温时,取出陶粒测其性能。通过对工艺条件的控制,系统研究凹凸棒石黏土添加量、煅烧温度、煅烧时间以及煤粉用量对陶粒性能的影响规律,得出浊沸石尾矿陶粒的优化制备工艺。

1.3 陶粒性能测试和表征

1.3.1 堆积密度分析

称量一定质量的样品放入量筒中,使量筒中固体样品的上平面与量筒刻度线保持一致,读出固体样品的体积。按照公式(1)计算其堆积密度:

$$ \rho = \frac{m}{v} $$ (1) m为样品质量(kg),v为样品体积(m3),ρ为样品的堆积密度(kg/m3)。

1.3.2 压裂力分析

取单个陶粒置于万能试验机中,以100 N/min的速度逐渐施加压力至陶粒破裂,记录传感器所示试验力峰值,记为单个颗粒压裂力。同一批次随机取10个颗粒测试其压裂力,取其平均值为该批次陶粒压裂力。

1.3.3 吸水率分析

取相同质量的陶粒于烧杯中,称其质量。向烧杯中加入相同质量的水。待1 h后,取出陶粒,用毛巾将陶粒表面的水擦干,再次称其质量。按照公式(2)计算其吸水率:

$$ p = \frac{{{m_1} - {m_0}}}{{{m_0}}} \times {\rm{ }}100\% $$ (2) p为吸水率(%);m0为干陶粒质量(g);m1为吸水陶粒质量(g)。

1.3.4 筒压强度

将陶粒倒入高度为100 mm的承压筒内,用木锤敲击承压筒四周使陶粒与筒口平齐,将承压筒放在万能试验机上,控制匀速加载荷速率为500 N/s,记录当冲压深度为20 mm时的压力值。按照公式(3)计算其筒压强度:

$$ f = \frac{P}{A} $$ (3) f为筒压强度(MPa);P为压入深度为20 mm时的压力值(N);A为冲压面积(mm2)。

1.3.5 扫描电镜分析

扫描电镜是利用电子束扫描样品表面产生高分辨率的样品表面图像,采用日本日立公司SU8010扫描电子显微镜进行检测。先使用真空喷镀仪对样品进行喷金处理,然后放入扫描电镜仪器中观察其微观形貌。

1.3.6 XRD物相分析

XRD物相分析是利用X射线照射晶体,依据晶体散射的规律确定晶体组成,采用德国布鲁克公司D8 ADVANCE X射线衍射仪进行检测,测试参数分别设置为:Cu靶,电压40 kV,电流40 mA,扫描速度8°/min。对XRD图谱数据进行分析,得到样品的晶相组成。

2. 结果与讨论

2.1 凹凸棒石黏土添加量对陶粒性能的影响

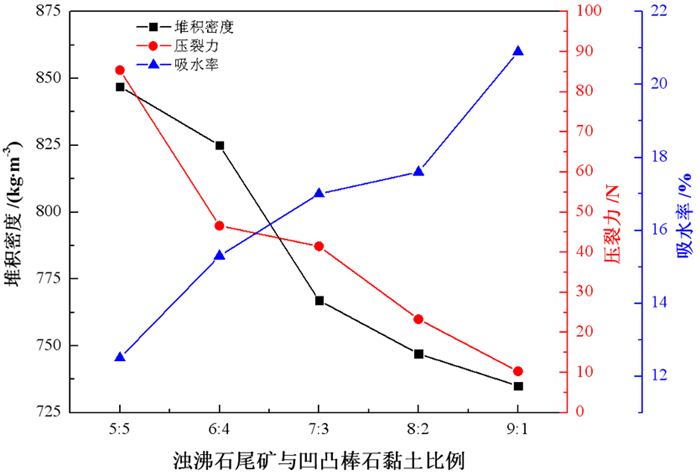

将浊沸石尾矿、凹凸棒石黏土分别以5:5、6:4、7:3、8:2、9:1的比例进行混合,在煅烧温度1 100 ℃、煅烧时间30 min、升温速率20 ℃/min的烧结制度条件下制备陶粒,探究不同配方条件对陶粒的压裂力、堆积密度及吸水率的影响规律,结果如图 1所示。

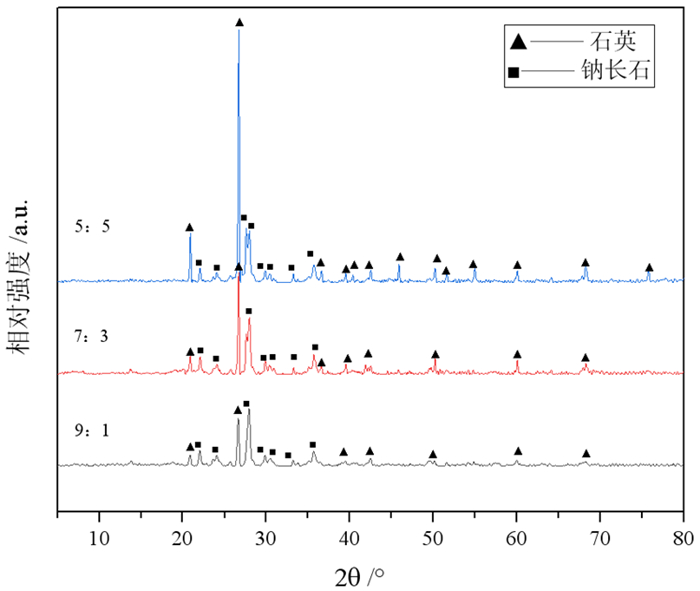

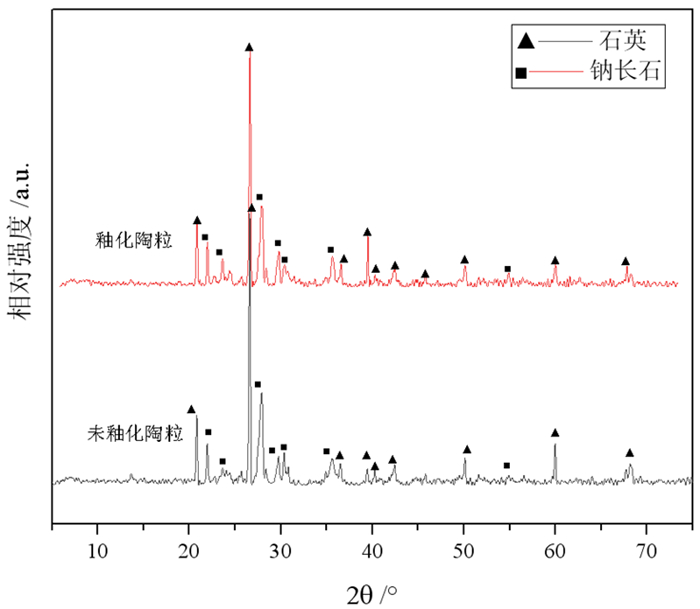

由图 1可知,随着凹凸棒石黏土添加量的不断增加,陶粒样品的堆积密度和压裂力不断增加,而吸水率有所降低,说明凹凸棒石黏土的添加使陶粒结构倾向于致密。凹凸棒石黏土中含有的坡缕石相在造粒过程中膨胀,为造粒成型提供必要的黏性,造成生料球致密性提高;另一方面,凹凸棒石黏土中含有较多的SiO2组分,凹凸棒石黏土的添加使得生料球的SiO2、Al2O3、助熔剂的比例落入Riley三相图中,补足了焙烧陶粒所需的原料要求。图 2为对浊沸石尾矿、凹凸棒石黏土比例分别为5:5、7:3及9:1条件下制备陶粒的XRD分析,由图 2可知,陶粒主要矿物成分为石英与钠长石,而陶粒XRD图谱中未出现原料中的浊沸石及坡缕石物相,这表明在1 100 ℃的条件下原料中的浊沸石、坡缕石完全转化为石英和钠长石。凹凸棒石黏土添加量较多时,XRD图谱中石英所对应的峰强度及峰面积最大,这说明凹凸棒石黏土的增加有助于陶粒中石英相的结晶,也利于陶粒强度的提升。当浊沸石尾矿、凹凸棒石黏土质量比为5:5时,陶粒强度达到最高,因此,选用沸石尾矿与凹凸棒石黏土质量比为5:5作为优化的陶粒配方条件。

2.2 煅烧温度对陶粒性能的影响

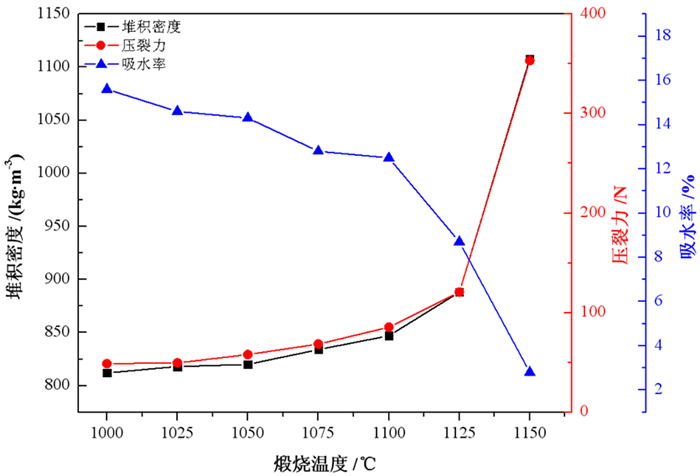

浊沸石尾矿与凹凸棒石黏土质量比5:5,在煅烧时间30 min、升温速度20 ℃/min的烧结制度条件下制备陶粒,探究不同煅烧温度对陶粒的压裂力、堆积密度及吸水率的影响规律,结果如图 3所示。

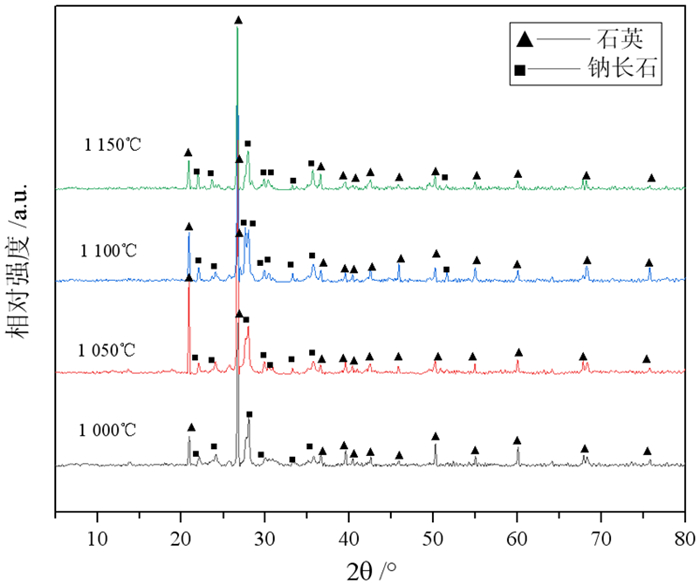

由图 3可知,随煅烧温度升高,陶粒的堆积密度和压裂力不断升高,而吸水率有所下降,在1 100 ℃时变化最为明显;当煅烧温度为1 150 ℃时,陶粒体积较小、表面光滑且泛黑;当煅烧温度为1 125 ℃时,有少部分陶粒外观同样呈上述状态。这是由于在高温条件下,陶粒表面发生了釉化。对这类表面釉化陶粒(煅烧温度为1 150 ℃)及未釉化陶粒(煅烧温度为1 100 ℃)分别进行扫描电镜测试,结果见图 4。由图 4可知,釉化陶粒表面不仅光滑而且还有少量大孔,但孔径分布不均匀,其内部结构较为致密,界面间含有部分孔洞结构;而未釉化的陶粒表面则相对粗糙,内部结构较为松散。这是因为当煅烧温度达到1 125 ℃以上时,陶粒内部气相与液相向外扩散,在内部形成孔洞结构,当扩散至陶粒表面后,气相逸出,液相则在陶粒表面转化为固相,形成质地坚硬光滑的表面,此时陶粒向内收缩,孔体积减少,整体呈“烧成收缩”反应,性能体现为密度和压裂力增大而吸水率降低。当煅烧温度大于1 100 ℃时,所制备的陶粒堆积密度、压裂力增长较快,而吸水率则快速减小。由图 5可知,当煅烧温度达1 000 ℃时,原料中沸石相、坡缕石相已完全消失;当煅烧温度达1 000 ℃以上时,随着煅烧温度的提高陶粒晶相变化不大且无新相生成。上述结果说明,陶粒釉化的过程主要是物理变化,并未涉及新相的生成。综上,兼顾密度、压裂力、吸水率三项性能指标,选用1 100 ℃作为煅烧温度的优化条件。

2.3 煅烧时间对陶粒性能的影响

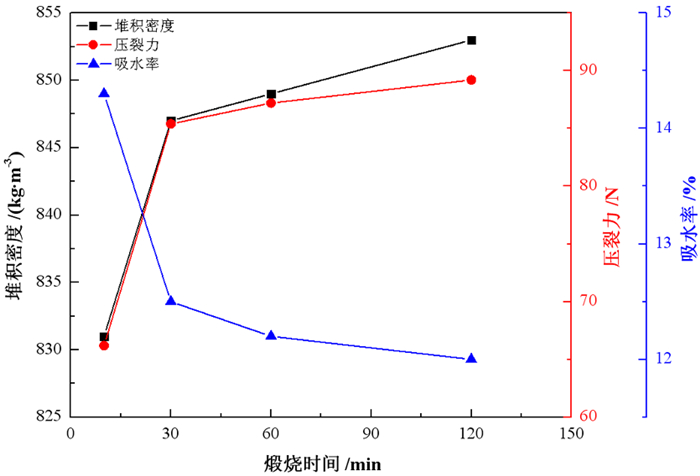

浊沸石尾矿与凹凸棒石黏土质量比5:5,在煅烧温度1 100 ℃、升温速度20 ℃/min的烧结制度条件下制备陶粒,探究不同煅烧温度对陶粒的压裂力、堆积密度及吸水率的影响规律,结果如图 6所示。

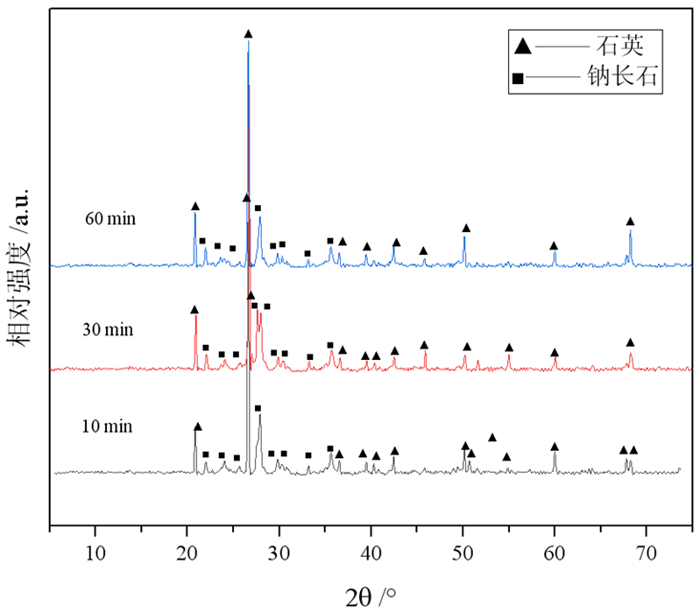

由图 6可知,当煅烧时间较短(10 min)时,陶粒尚未烧成,陶粒抗压裂力较小;当煅烧时间延长至60 min以上时,陶粒抗压碎力增长缓慢。因此,在煅烧温度确定为1 100 ℃的情况下,延长煅烧时间并不能明显提高陶粒的力学性能,而煅烧时间过短则会使陶粒烧结不充分,造成力学性能较差。图 7为不同煅烧时间条件下陶粒的XRD图谱,由图 7可知,在1 100 ℃下,以10 min、30 min、120 min为煅烧时间所得陶粒晶相结构区别不大,主要为石英和钠长石,说明煅烧温度为1 100 ℃左右时陶粒的烧结过程没有晶相结构变化,主要为物理反应。综上,考虑到高温煅烧所需能耗较高,选用30 min作为煅烧时间的优化条件。

2.4 煤粉用量对陶粒性能的影响

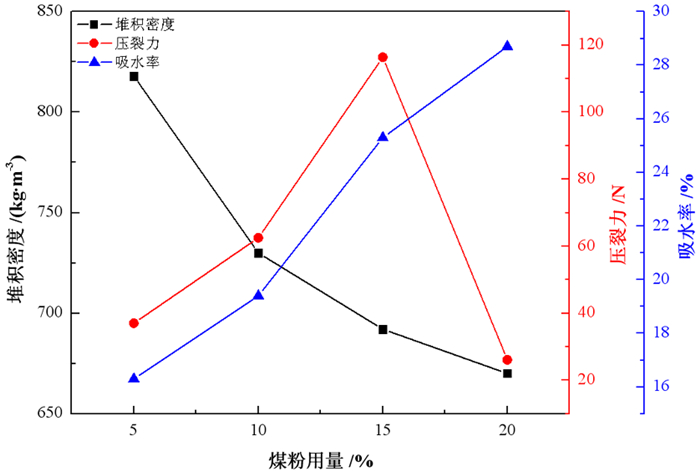

浊沸石尾矿与凹凸棒石黏土质量比为5:5,复配煤粉作为造孔剂,在煅烧温度1 100 ℃、煅烧时间30 min,升温速度20 ℃/min的烧结制度条件下制备陶粒,探究煤粉用量对陶粒的压裂力、堆积密度及吸水率的影响规律,结果如图 8所示。

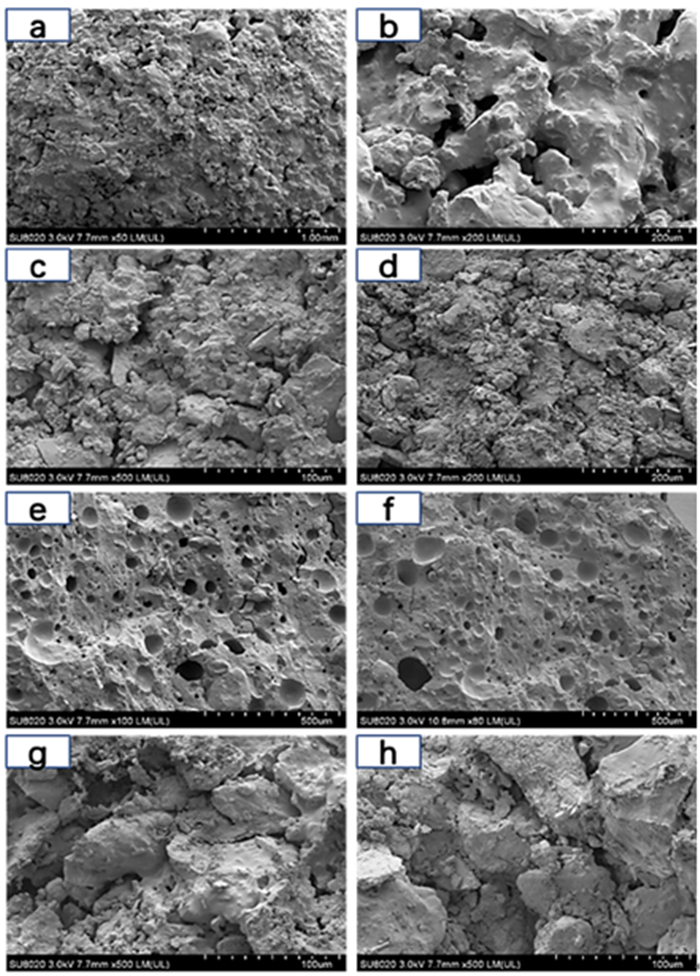

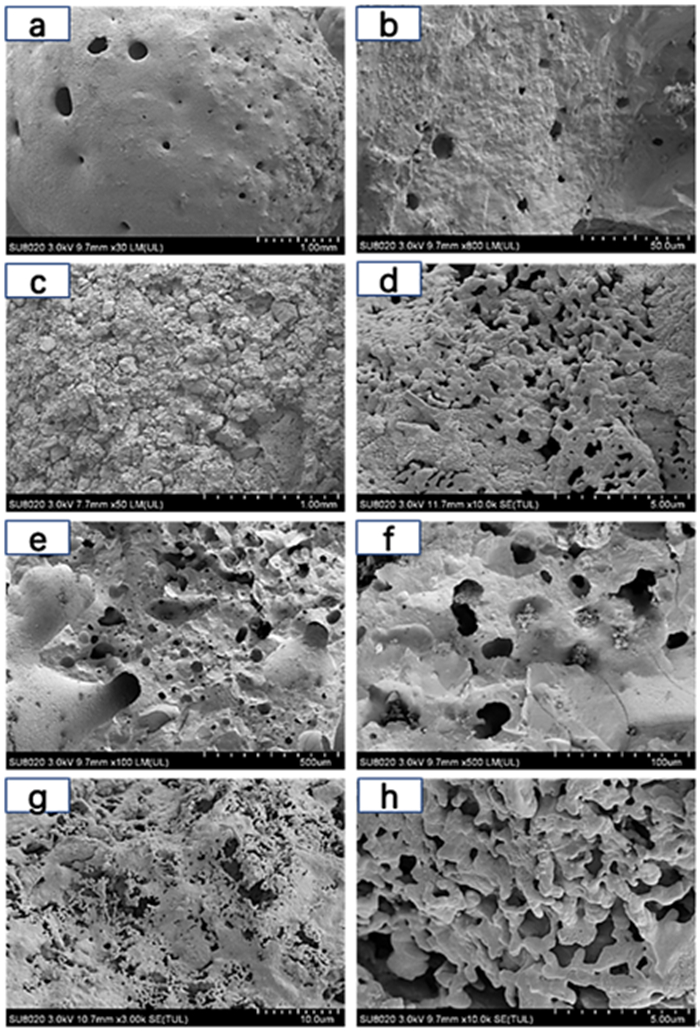

由图 8可知,添加煤粉作为造孔剂不仅可以有效降低陶粒的堆积密度,还可以显著增大其吸水率,且压裂力随煤粉添加量增大也不断提高,但煤粉添加量较多(20%)时,压裂力则迅速降低。这是因为当煤粉添加量为10%、15%时所得陶粒表面均有一定的釉化,而釉化颗粒的强度较大。对釉化陶粒和未釉化陶粒进行SEM和XRD分析如图 9和图 10所示,由图 9可知,釉化陶粒的表面较为光滑且有大孔,而未釉化的陶粒表面粗糙且有不规则小孔。从截面来看,釉化陶粒截面孔道结构明显,而未釉化陶粒孔道小且分布不均匀。这是因为釉化的过程中造孔剂产生的气相相互流通至表面形成气孔,而未釉化颗粒中气体则是以小孔散逸至表面。由图 10可知,釉化陶粒、未釉化陶粒的XRD图谱基本一致,主要成分均为石英和钠长石,并无新相生成。

![]() 图 9 以煤粉为造孔剂制备的陶粒样品的SEM微观形貌;(a、b)釉化陶粒表面;(c、d)未釉化陶粒表面;(e、f)釉化陶粒截面、(g、h)未釉化陶粒截面Figure 9. SEM morphologies of ceramsite sample prepared with pulverized coal as pore-forming agent, (a, b) glazed ceramsite surface, (c, d) unglazed ceramsite surface, (e, f) glazed ceramsite cross section, (g, h) unglazed ceramsite cross section

图 9 以煤粉为造孔剂制备的陶粒样品的SEM微观形貌;(a、b)釉化陶粒表面;(c、d)未釉化陶粒表面;(e、f)釉化陶粒截面、(g、h)未釉化陶粒截面Figure 9. SEM morphologies of ceramsite sample prepared with pulverized coal as pore-forming agent, (a, b) glazed ceramsite surface, (c, d) unglazed ceramsite surface, (e, f) glazed ceramsite cross section, (g, h) unglazed ceramsite cross section对釉化、未釉化陶粒分别进行强度检测,结果见表 8。由表 8可知,煤粉添加量为15%时所得釉化陶粒和未釉化陶粒强度均最大,这是因为未釉化陶粒同样已经开始其釉化过程,且此时陶粒釉化率最高,达58%。综上,选用15%作为煤粉添加量的优化条件。

表 8 煤粉添加量对陶粒釉化的影响Table 8. Influence of addition amount of pulverized coal on glaze of ceramsite煤粉添加量/% 釉化率/% 釉化陶粒压裂力/N 未釉化陶粒压裂力/N 5 13 119.5 16.3 10 39 139.6 19.4 15 58 196.4 35.3 20 14 126.1 易碎 经进一步测试,实验室优化条件下制备的浊沸石尾矿陶粒的堆积密度为692 kg/m3,筒压强度为4.7 MPa,属国标700密度级陶粒,其堆积密度和筒压强度均达到国家相关标准。

3. 结论

(1) 以浊沸石尾矿为基体材料,凹凸棒石黏土为黏结剂,煤粉为造孔剂,在浊沸石尾矿、凹凸棒石黏土与煤粉的质量比为42.5:42.5:15,煅烧温度1 100 ℃,煅烧时间30 min,升温速度20 ℃/min的条件下制备出了性能良好的多孔陶粒,其堆积密度和筒压强度均符合《GB/T 17431.1—2010轻集料及其试验方法》的要求。该技术为砂石尾矿综合利用提供了一种有效途径,有利于促进砂石行业的绿色发展。

(2) 浊沸石尾矿陶粒主要成分为石英及长石族矿物,在煅烧过程中原料中的浊沸石、绿泥石、坡缕石等矿物发生晶相转变,生成石英及长石族矿物。此外,高温条件下陶粒内部气相与液相向外扩散,扩散至陶粒表面后,气相逸出形成孔洞,液相则在陶粒表面转化为固相,形成质地坚硬光滑的表面层。

-

图 9 以煤粉为造孔剂制备的陶粒样品的SEM微观形貌;(a、b)釉化陶粒表面;(c、d)未釉化陶粒表面;(e、f)釉化陶粒截面、(g、h)未釉化陶粒截面

Figure 9. SEM morphologies of ceramsite sample prepared with pulverized coal as pore-forming agent, (a, b) glazed ceramsite surface, (c, d) unglazed ceramsite surface, (e, f) glazed ceramsite cross section, (g, h) unglazed ceramsite cross section

表 1 浊沸石尾矿粒度分析结果

Table 1 Granularity analysis results of laumontite tailings

粒度级 D10 D50 D90 D97 粒径/μm 1.43 6.42 16.71 19.02 表 2 浊沸石尾矿的主要化学成分分析结果

Table 2 The main chemical components and content analysis results of laumontite tailings

氧化物 SiO2 Al2O3 CaO Fe2O3 MgO K2O Na2O TiO2 含量/% 47.4 18.6 12.2 12.3 4.88 1.19 1.47 1.09 表 3 浊沸石尾矿的XRD物相分析结果

Table 3 XRD phase analysis results of laumontite tailings

矿物 沸石 绿泥石 长石 石英 磁铁矿 云母 含量/% 52.8 18.4 18.0 5.9 2.7 2.2 表 4 凹凸棒石黏土的主要化学成分分析结果

Table 4 The main chemical components and content analysis results of attapulgite clay

氧化物 SiO2 CaO Al2O3 MgO 其他 含量/% 87.6 4.5 3.6 3.1 1.2 表 5 凹凸棒石黏土的XRD物相分析结果

Table 5 XRD phase analysis results of attapulgite clay

矿物 石英 坡缕石 白云石 含量/% 75.4 16.7 7.9 表 6 煤粉灰分的主要化学成分分析结果

Table 6 The main chemical components and content analysis results of pulverized coal ash

氧化物 SiO2 Al2O3 Fe2O3 CaO MgO K2O 其他 含量/% 48.10 27.70 10.00 6.81 2.45 2.08 2.84 表 7 煤粉灰分的XRD物相分析结果

Table 7 XRD phase analysis results of pulverized coal ash

矿物 高岭石 石英 菱铁矿 白云石 含量/% 69.3 15.1 10.4 5.2 表 8 煤粉添加量对陶粒釉化的影响

Table 8 Influence of addition amount of pulverized coal on glaze of ceramsite

煤粉添加量/% 釉化率/% 釉化陶粒压裂力/N 未釉化陶粒压裂力/N 5 13 119.5 16.3 10 39 139.6 19.4 15 58 196.4 35.3 20 14 126.1 易碎 -

[1] 肖如华, 邬红生. 水泥稳定碎石基层施工技术在公路施工中的应用[J]. 黑龙江交通科技, 2020, 43(11): 54-56. DOI: 10.3969/j.issn.1008-3383.2020.11.031 [2] 胡幼奕. 砂石骨料产业转型升级及应建立的新模式[J]. 混凝土世界, 2015(9): 16-19. DOI: 10.3969/j.issn.1674-7011.2015.09.004 [3] 刘峻铭. 甘肃省砂石骨料开发利用现状及建议[J]. 中国矿业, 2020, 29(S2): 8-10. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKA2020S2002.htm [4] 任雯. 普通建筑用砂石类矿产的开发利用现状及对策[J]. 住宅与房地产, 2020(15): 104. https://www.cnki.com.cn/Article/CJFDTOTAL-ZZFD202015090.htm [5] 王欢. 姑山矿业尾矿利用现状及发展前景[J]. 现代矿业, 2021, 37(1): 126-127, 144. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKB202101038.htm [6] 米晓凡, 范海宏, 贾璐卫, 等. 烧结温度对钢渣陶粒结构及性能的影响[J]. 非金属矿, 2021, 44(1): 36-39. DOI: 10.3969/j.issn.1000-8098.2021.01.011 [7] 刘玉洁, 曹瑞华, 王家宏. 凹凸棒基陶粒的制备及其去除水中磷的研究[J]. 陕西科技大学学报, 2021, 39(2): 100-105. DOI: 10.3969/j.issn.1000-5811.2021.02.016 [8] LIANGKAI, W., YALU, S., ZILONG, Z. Optimized utilization studies of dredging sediment for making water treatment ceramsite based on an extreme vertex design[J]. Journal of Water Process Engineering, 2020, 38: 101603. DOI: 10.1016/j.jwpe.2020.101603

[9] JOANNA, C., A., T. J., ADAM, M., et al. Powdered ceramsite and powdered limestone use in aerobic granular sludge technology[J]. Materials, 2020, 13(17): 3894 DOI: 10.3390/ma13173894

[10] HANXI, W., JIANLING, X., YUNQING, L., et al. Preparation of ceramsite from municipal sludge and its application in water treatment: A review[J]. Journal of environmental management, 2021, 287: 112374. http://www.sciencedirect.com/science/article/pii/S0301479721004369

[11] 汪学彬, 杨重卿, 张祥伟, 等. 工业固体废弃物制备陶粒及其应用研究进展[J]. 中国粉体技术, 2021, 27(2): 1-8. https://www.cnki.com.cn/Article/CJFDTOTAL-FTJS202102001.htm [12] 段美学, 闫传霖, 赵蔚琳. 利用金矿尾矿烧制陶粒的正交试验研究[J]. 中国粉体技术, 2014, 20(4): 64-67. https://www.cnki.com.cn/Article/CJFDTOTAL-FTJS201404021.htm [13] 刘代俊. 中国无机固体废弃物处理技术进展[J]. 无机盐工业, 2020, 52(3): 1-10. https://www.cnki.com.cn/Article/CJFDTOTAL-WJYG202003002.htm [14] 郝晓平, 韩进文, 高志强, 等. 锌冶炼废渣的综合利用[J]. 无机盐工业, 2017, 49(7): 55-58. https://www.cnki.com.cn/Article/CJFDTOTAL-WJYG201707015.htm [15] 童思意, 刘长淼, 刘玉林, 等. 我国固体废弃物制备陶粒的研究进展[J]. 矿产保护与利用, 2019, 39(3): 140-150. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=7b9ca98f-8c63-45a8-9a8e-20c2b0731f52 [16] 姚绍武, 张文彬, 夏朝科. 利用石矿尾泥加工轻质陶粒的工艺可行性研究[J]. 矿业工程, 2018, 16(4): 60-63. https://www.cnki.com.cn/Article/CJFDTOTAL-GWKS201804020.htm [17] 张铨昌, 张振禹, 戴长禄. 浊沸石-一种有用的矿物[J]. 地质科学, 1986(4): 419. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKX198604014.htm

下载:

下载: